Fout in e-mailformaat

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nieuws

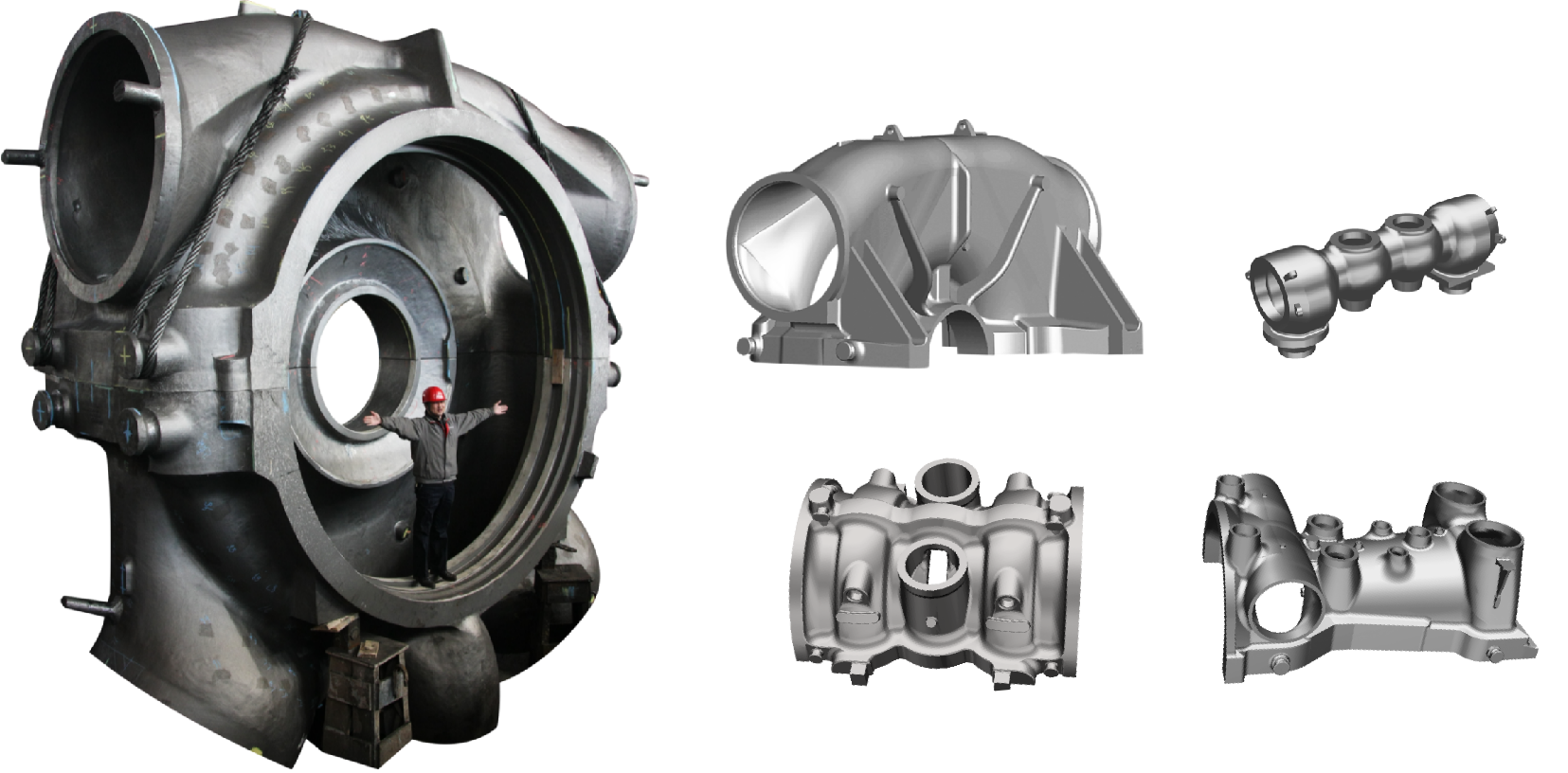

The Mystery of Sand Casting Technology

Casting is a forming method of smelting metal, manufacturing mold, pouring molten metal into a mold, and obtaining metal parts blank with a certain shape, size, and performance after solidification.

Sand casting is a casting method that uses a sand mold to fill molten metal into the mold under the action of gravity.

The ability of a tight sand mold to let gas escape through it is called permeability.

Under the thermal action of liquid metal, the mold produces a lot of gas. If the sand mold and sand core do not have good exhaust capacity, choking may occur during the pouring process, resulting in defects such as pores and pouring failure.

On the one hand, the exhaust capacity of the sand mold depends on the riser and penetrating or nonpenetrating air outlet, on the other hand, it depends on the permeability of molding sand.

There are many factors affecting air permeability, mainly including:

- Raw sand. The size, particle size distribution, particle shape, and mud content of sand will affect the permeability. The raw sand with round, coarse particles, uniform particle size, and less mud content has better air permeability.

- Compactness of molding sand and ash in old sand. The higher the compactness of the sand mold, the smaller the gap, and the lower the permeability. However, when the compactness reaches a certain degree, the permeability changes little. When the ash content of pulverized coal, clay, and talc in clay sand is high, the permeability decreases.

- Type and amount of binder. The type of binder and whether it will burn, evaporate or decompose at high temperature have a certain impact on the permeability. The excessive addition of various binders such as clay, resin, and water glass will reduce the void and permeability of molding sand.

- Type and amount of additives. Additives such as pulverized coal in clay sand and iron oxide powder added in resin sand have a certain impact on air permeability.

- Sand mixing process. When mixing sand, the binder is evenly coated on the surface of the raw sand, and the permeability can be improved by homogenizing and loosening the molding sand.

- Coating condition and thickness of coating layer. Sand mold without coating has high air permeability. The coating layer is thick and has poor air permeability. Some additives in the paint will leave gaps after high-temperature combustion, which will improve air permeability.

It should be noted that it should not be misunderstood that the higher the permeability of molding sand, the better because it shows that the larger the diameter of the sand gap, the liquid metal is easy to penetrate the pores between sand particles, resulting in rough casting surface and mechanical sand sticking.

We are a sand casting design, sand casting set, parts of sand casting exporter supplier wholesaler, our products satisfy our customers. And we want to be your long-term partner, any interests, welcome to contact us.